Ball Screw

(Total 54 Products)

-

-

ZPW-3.7C touch sensor for mine wireless automatic sprinkler

Contact Now

-

-

-

-

ZPW3.7 Mine Wireless Automatic Sprinkler Dust Reduction

Contact Now

-

-

-

the ZP127 Mining Automatic Dust Reduction Device

Contact Now

-

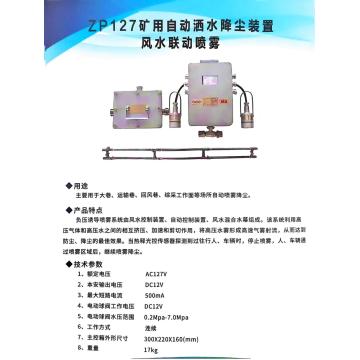

the ZP127 Mining Fully Automatic Dust Reduction Device

Contact Now

-

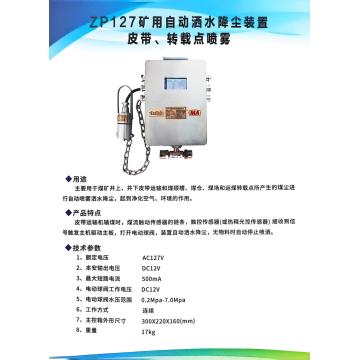

Mining Automatic Wine Dust Reduction Device Belt

Contact Now

-

-

Intrinsically Safe Headsets for Hazardous Environments

Contact Now

-

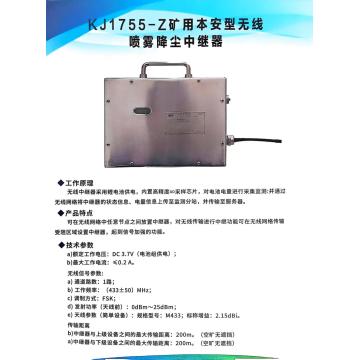

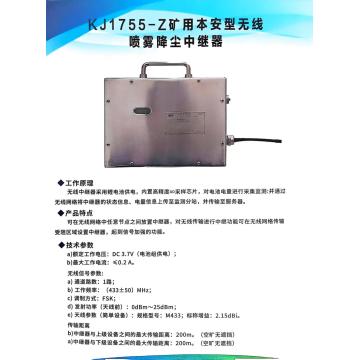

KJ1755-Z Intrinsically Safe Wireless Spray Dust Repeater

Contact Now

-

-

-

-

-

-

ZPW3.7 Mining Wireless Automatic Dust Reduction Device

Contact Now

-

-

-

High-precision grinding trapezoidal lead screw

Contact Now

-

-

Product Description: Ball Screw The ball screw rotating nut is a precision mechanical component designed to convert rotational motion into linear motion with high efficiency and accuracy. This product, known as the lead screw rotating nut, plays a...

-

Unit Price:USD 34 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

◆ How it worksThis device is suitable for the environment where there is a danger of methane and coal dust explosion, and the sensor is used with the host of ZPW3.7-Z mine intrinsically safe wireless automatic wine dust reduction device. In...

-

Unit Price:USD 25 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

Tester screws

The lead screw of the testing machine mainly regulates the test loading space.Which testing machines are the lead screws mainly used in? Bojian testing machine manufacturers will answer for you: the lead screw is used in electronic...

-

Unit Price:USD 25 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

Tester screws

The lead screw of the testing machine mainly regulates the test loading space.Which testing machines are the lead screws mainly used in? Bojian testing machine manufacturers will answer for you: the lead screw is used in electronic...

-

Unit Price:USD 25 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

Tester screws

The lead screw of the testing machine mainly regulates the test loading space.Which testing machines are the lead screws mainly used in? Bojian testing machine manufacturers will answer for you: the lead screw is used in electronic...

-

Unit Price:USD 34 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

ZPW3.7 Mine Wireless Automatic Sprinkler Dust Reduction Device Fully Mechanized Mining Face Support Spraying Mist

Work PurposeIt is mainly used for automatic spray dust reduction between the supports of the fully mechanized coal mining...

-

Unit Price:USD 12 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

Cold-rolled ball screws

The cold rolling of a ball screw is made by cutting a groove of a certain depth in the smooth rod material, and the groove pitch is equal to the processing line pitch, and then rolling it with similar threads. The rolling of...

-

Unit Price:USD 12 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

Cold-rolled ball screws

The cold rolling of a ball screw is made by cutting a groove of a certain depth in the smooth rod material, and the groove pitch is equal to the processing line pitch, and then rolling it with similar threads. The rolling of...

-

Unit Price:USD 34 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

> usesIt is mainly used in the main roadway, transportation belt roadway, return air roadway, bottom of the well, parking lot and other places. Reduce the concentration of coal dust, dust, carbon monoxide and gas in the underground and improve...

-

Unit Price:USD 34 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

useIt is mainly used for automatic spraying and dust reduction in alleys, transportation alleys, return air alleys, fully mechanized mining faces and other places.Features:The negative pressure induced spray system is composed of a feng shui control...

-

Unit Price:USD 34 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

> usesIt is mainly used for automatic spraying of coal dust generated by coal mine upper, underground belt transportation and coal trough, coal bunker, coal yard and coal transportation transfer point, which plays a role in purifying the air and...

-

Min. Order:1

Model No:1616、2020、2525、3232、4040

Ball Screw with Large Pitch, High-Pitch Ball Screw, and Large Lead & Pitch Ball Screw are specialized mechanical components designed to convert rotational motion into linear motion with high efficiency and precision. These ball screws are ideal...

-

Unit Price:USD 34 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

◆ How it worksThe wireless repeater is powered by a carp battery, with a built-in high-precision AD sampling chip, which collects and monitors the battery power: uploads the status information and power information of the repeater to the monitoring...

-

Unit Price:USD 34 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

◆ How it worksThe wireless repeater is powered by a carp battery, with a built-in high-precision AD sampling chip, which collects and monitors the battery power: uploads the status information and power information of the repeater to the monitoring...

-

Min. Order:1

Model No:1605

Internal circulation ball screw nut, external circulation ball screw nut, and integrated ball screw nut are essential components in precision motion control systems, widely used across various industrial applications. These ball screw nuts play a...

-

High lead ball screw is a specialized mechanical component designed to convert rotational motion into linear motion with high efficiency and precision. This product, known as precision large lead screw or ball screw with large lead, is widely used...

-

Micro lead screw precision components are essential for achieving high accuracy and reliability in a wide range of mechanical applications. These small lead screw components are designed to provide precise linear motion with minimal backlash, making...

-

Precision miniature ball screw, miniature ball screw system, and compact ball screw mechanism are essential components in modern engineering applications that demand high accuracy, reliability, and efficiency. These specialized devices are designed...

-

Min. Order:1

Model No:2004、2505、3210

Special-shaped Nut Ball Screw, Non-standard Nut Ball Screw, and Custom-shaped Nut Ball Screw are advanced mechanical components designed to provide precise linear motion in a wide range of industrial applications. These specialized ball screws are...

-

Unit Price:USD 34 / Piece/Pieces

Min. Order:100 Piece/Pieces

Transportation:Land

How it worksIt is mainly used for automatic spraying of coal dust generated by coal mine upper, underground belt transportation and coal trough, coal bunker, coal yard and coal transportation transfer point, which plays a role in purifying the air...

-

Min. Order:1

Model No:3210、4010、5010

Ball Screw: Precision Cold-Rolled Ball Screw for High-Performance ApplicationsOverviewThe precision cold-rolled ball screw is a high-quality mechanical component designed to convert rotational motion into linear motion with exceptional accuracy and...

-

High Precision Ball Screw and Double Nut Ball Screw System for Precision Lead Screw Assembly The high precision ball screw is a critical component in modern industrial machinery, offering exceptional accuracy, reliability, and efficiency. Designed...

-

When it comes to precision motion control, the ball screw stands as a cornerstone in modern engineering and manufacturing. This product, known as a precision trapezoidal lead screw, high accuracy grinding lead screw, or precision ground trapezoidal...

-

High precision ball screw for electric car is a critical component designed to enhance the performance and efficiency of electric vehicle systems. As the automotive industry continues to shift towards sustainable and advanced technologies, the...

Ball screws, also known as Ball Screw drives, are high-precision mechanical transmission components designed to convert rotary motion into linear motion (or linear motion into rotary motion) with minimal friction. They are core components in precision machinery, relying on rolling steel balls between the screw shaft and nut to replace the sliding friction of traditional lead screws, delivering high efficiency, positioning accuracy, and service life, and are widely used in CNC machine tools, robotics, aerospace equipment, and automotive manufacturing. ## Basic Structure A ball screw assembly consists of four core components, working together to achieve precise motion transmission: - **Screw Shaft**: A cylindrical shaft with a helical raceway machined on its surface, made of high-strength alloy steel (such as 40Cr or SUJ2) and hardened to HRC 58-62 to ensure wear resistance. The helical raceway is precision-ground to a smooth surface, reducing friction with the steel balls. - **Nut**: A hollow component matching the screw shaft, with a corresponding helical raceway on its inner surface. It is also made of hardened alloy steel, and some high-precision nuts are designed with a recirculation system for the steel balls. - **Steel Balls**: Small, high-hardness bearing steel balls (usually GCr15) that roll between the screw and nut raceways, converting sliding friction into rolling friction. The size and quantity of the steel balls are determined according to the load and precision requirements of the ball screw. - **Recirculation System**: A structure that guides the steel balls back to the start of the raceway after they reach the end of the nut, enabling continuous rolling. There are two main types: external recirculation (using a tube to guide balls) and internal recirculation (using a built-in reverse device), with internal recirculation offering a more compact structure. --- ## Working Principle The operation of a ball screw relies on the rolling motion of steel balls to achieve efficient motion conversion: 1. **Motion Conversion**: When the screw shaft rotates, the steel balls roll along the helical raceway, driving the nut to move linearly along the shaft. Conversely, when an external force pushes the nut to move linearly, the steel balls roll to drive the screw shaft to rotate. 2. **Friction Reduction**: The rolling contact between the steel balls and the raceways reduces friction to 1/10 or less of that of traditional sliding lead screws, improving transmission efficiency (up to 90-98%) and reducing energy consumption. 3. **Precision Maintenance**: The precision-ground raceways and uniform steel ball size ensure consistent motion accuracy. Preloaded ball screws (with a slight interference fit between the screw and nut) can eliminate backlash, achieving positioning accuracy within ±0.001 mm per 300 mm of travel. --- ## Core Performance Specifications Ball screws meet strict performance standards for precision mechanical applications: | Performance Parameter | Typical Range | Key Function | | ---- | ---- | ---- | | Transmission Efficiency | 90-98% | Reduces energy consumption compared to sliding lead screws | | Positioning Accuracy | ±0.001 to ±0.05 mm/300mm | Ensures precise positioning in CNC and robotic systems | | Axial Load Capacity | 1,000 to 100,000 N | Withstands linear working loads in heavy-duty equipment | | Rotational Speed | Up to 5,000 rpm | Adapts to high-speed motion in automated machinery | | Service Life | 10,000 to 100,000 hours (under rated load) | Reduces maintenance frequency for long-term operation | In addition, ball screws have low heat generation during operation, and high-precision models can maintain consistent performance even after long-term continuous use. --- ## Key Advantages - **High Efficiency**: Far higher transmission efficiency than traditional sliding lead screws, reducing the required driving power and energy consumption - **High Precision**: Can achieve micron-level positioning accuracy, meeting the requirements of precision machining and automated assembly - **Long Service Life**: The rolling friction design reduces wear, extending the service life of the component by 3-5 times compared to sliding lead screws - **Low Backlash**: Preloaded ball screws can eliminate axial backlash, ensuring reverse motion accuracy and stability - **Low Maintenance**: The sealed recirculation system reduces the need for lubrication and maintenance, improving equipment uptime --- ## Applications Ball screws are used in all types of precision machinery that require linear motion transmission: - **CNC Machine Tools**: Used in the feed axes of milling machines, lathes, and grinders, ensuring precise cutting and positioning - **Robotics**: Used in the joint actuators and linear modules of industrial robots, enabling smooth and accurate motion - **Aerospace**: Used in aircraft flight control systems and satellite positioning mechanisms, withstanding extreme environmental conditions - **Automotive Manufacturing**: Used in automated assembly lines and vehicle testing equipment, improving production efficiency and precision - **Medical Equipment**: Used in surgical robots and diagnostic equipment, ensuring precise and stable motion --- ## Installation and Maintenance ### Installation Precautions 1. **Alignment Check**: Ensure the screw shaft is coaxial with the installation base, avoiding misalignment that could cause increased friction or wear 2. **Lubrication**: Apply a suitable lubricant (grease or oil) to the raceways before installation to reduce initial friction 3. **Sealing Protection**: Install the provided dust seals to prevent dust or debris from entering the raceways, which could damage the steel balls and raceways ### Maintenance Tips 1. **Regular Lubrication**: Replenish lubricant every 3-6 months (depending on usage frequency) to maintain smooth rolling of the steel balls 2. **Cleaning**: Regularly clean the surface of the screw shaft and nut with a clean, dry cloth to remove dust and debris 3. **Inspection**: Check for wear, noise, or reduced motion accuracy during equipment maintenance; replace the ball screw if abnormalities are found

Ball screws, also known as ball screw drives, are high-precision mechanical transmission components designed to convert rotary motion into linear motion (or linear motion into rotary motion) with minimal friction.

QUALIFICATIONS AND HONORS

Trademark Registration Certificate

Quality Management System Certification

Quality Management System Certification

Jining Luying Machinery Manufacturing Co., Ltd.

We travel to the ends of the earth in search of theworld's finest fibres. Once home with us in italy.we transform them in sublime garments throughtime-honoured manufacturing techniques